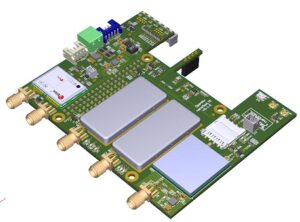

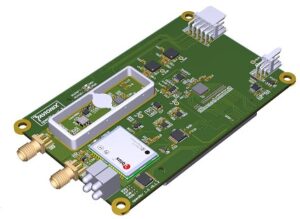

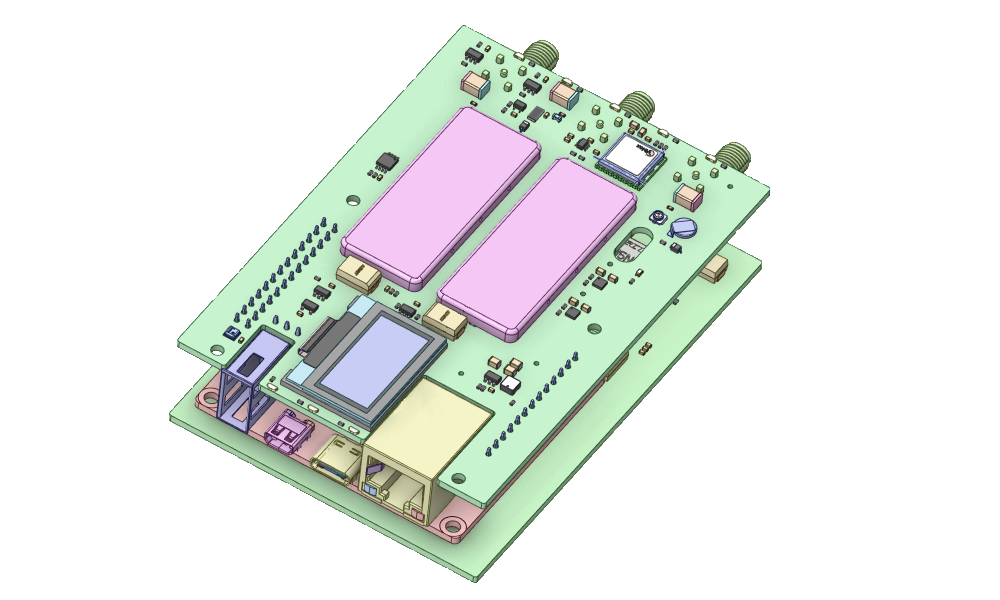

Hardware Project

Designing hardware for aerospace avionics involves precise engineering to capture and process signals from aircraft and satellites. Engineers focus on signal analysis, material selection for durability, integrating signal processing tech, and efficient power management to ensure reliable and accurate reception of signals for communication and navigation purposes.

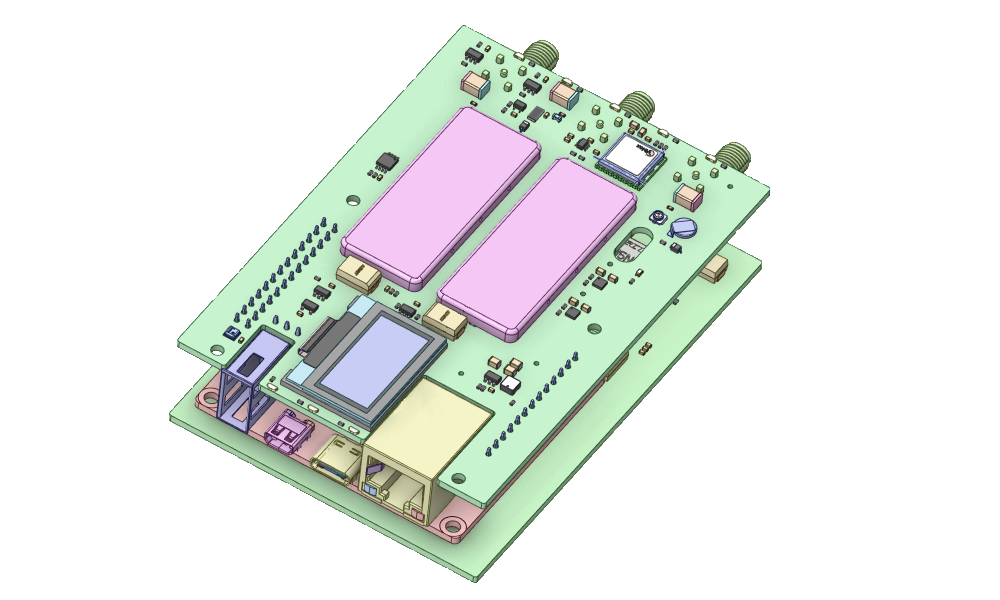

Project to Reality

Turning the hardware design into reality involves creating prototypes, rigorous testing, iterative improvements, and scaling up for manufacturing. Collaboration and precision are key to achieving a reliable aerospace avionics.

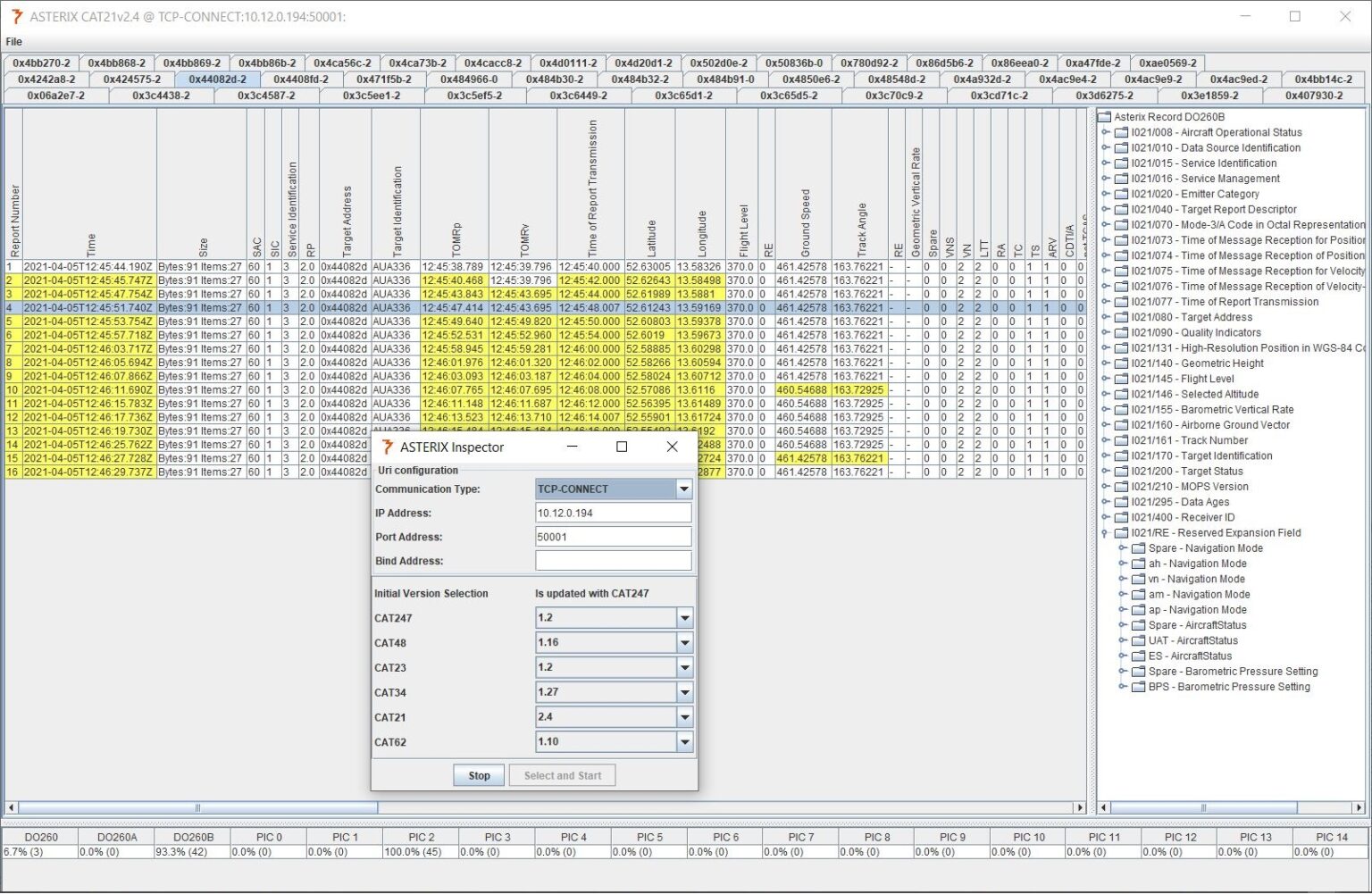

Testing with Dedicated Apparatus

Rigorous testing of avionics is conducted using specialized software and testing equipment. This ensures the components function optimally and meet required aviation standards.

Fixing the Complications

After testing, any detected issues or malfunctions are meticulously addressed. Engineers work to rectify problems, refine the design, and enhance overall avionics performance.

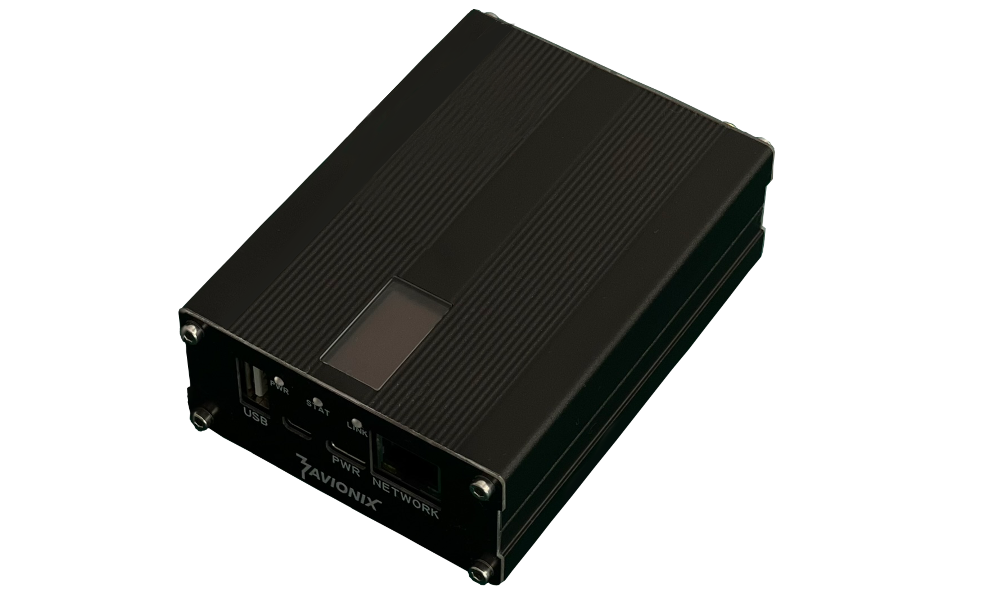

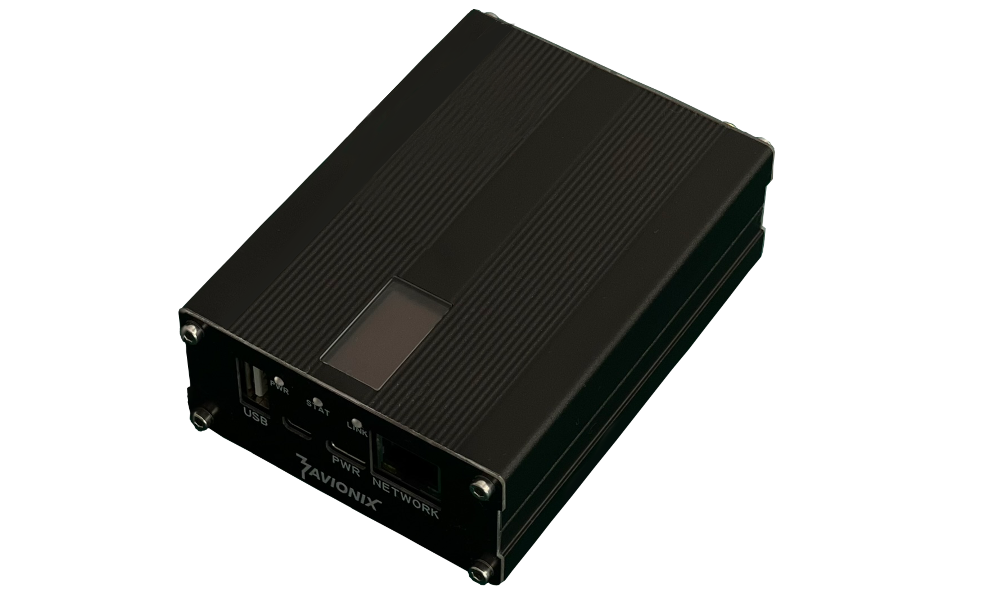

Packaging

Prior to shipping, the avionics components are securely packaged to endure transportation. Every precaution is taken to ensure they reach their destination intact, maintaining their functionality and quality.

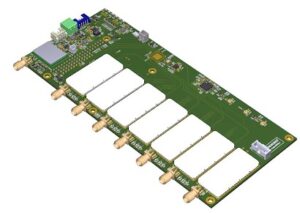

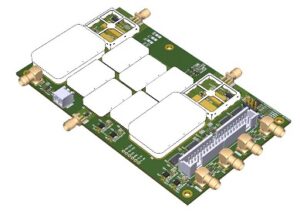

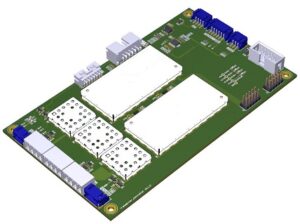

Assembling Aerospace Electronics

Our systems and software solutions are complemented by suitable equipment and necessary hardware. We care about installing, launching and maintaining all components.

- State-of-the-art ADS-B and Multilateration Surveillance Systems

- Frequency Monitoring and other systems related to RF technology

- Embedded devices, outdoor equipment

- Xilinx ZYNQ-7000 / UltraScale+

- (Preventive) IT-Maintenance (2nd and/or 3rd level)

- Worldwide provision of equipment and introduction of IT-systems

- After-sale care and change request management

Hardware Tests

At AVIONIX ENGINEERING, we prioritize quality and precision in every step of our product development process. Assembled products undergo rigorous testing to ensure they meet the highest standards of performance, safety, and reliability.

Our testing procedures begin immediately after the assembly phase is completed. Each assembled product is carefully examined by our highly skilled and experienced quality control team. This team employs a comprehensive set of tests and inspections tailored to the specific product type and industry requirements.

The testing process includes functional assessments to confirm that the product operates according to design specifications and meets intended performance benchmarks. We evaluate key components and subsystems to verify their integrity and integration, ensuring seamless functionality.

In addition to functionality, we conduct stability tests to assess the product's durability.

Furthermore, we meticulously evaluate safety features, compliance with regulatory standards, and adherence to industry certifications. Our testing protocols are designed to address potential safety concerns and guarantee that our products are compliant with relevant industry regulations.

The data gathered from these tests is analyzed in detail, and any discrepancies or deviations from the defined criteria are thoroughly investigated. We believe in continuous improvement and use the insights gained from testing to refine our manufacturing processes and enhance our products' overall quality.